I got a little closer to understanding the problem today. But first a brief explanation of how I have been testing this plug-in. This is an explanation I provided one of the respondents to my thread re the circuit behavior. Of course, a more complete description if available in the 7D14 service manual. SO, here goes:

The 7D14 has two inputs: the TRIGGER SOURCE, which is introduced to the counter from pins 20A/20B of the plug-in connector. The other input is the "CH A INPUT" BNC on the front panel of the counter. The counter selects these by means of the "INPUT SENS" [sic] switch on the front panel. It has six positions: 50Ω 1V and 100mV, "TRIG SOURCE", 1MΩ 100 mV, 1V, 10V going clockwise on the face.

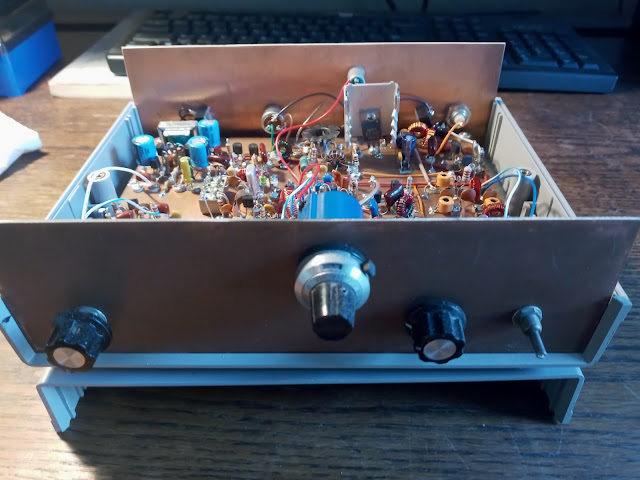

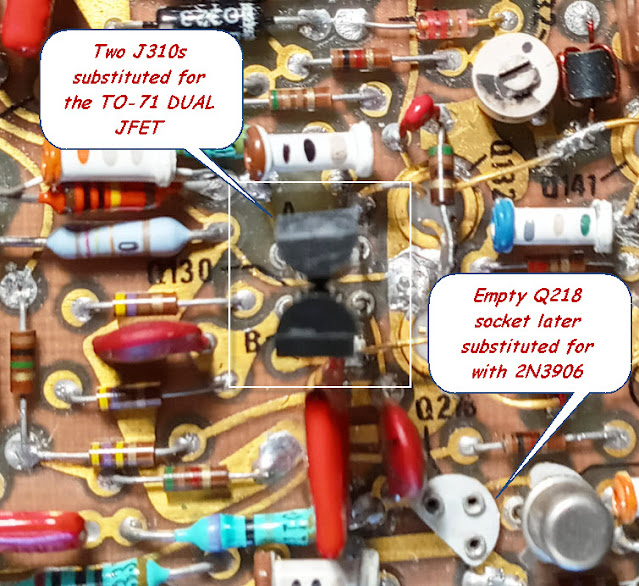

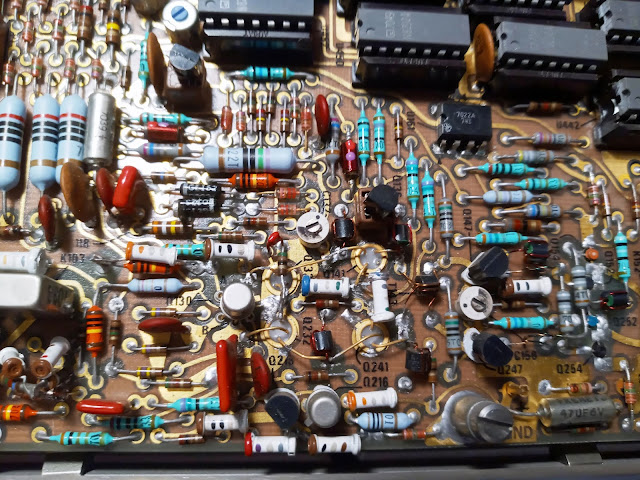

The 50Ω and 1MΩ positions activate/deactivate various relays to run the signal through resistor pads and to achieve the designated attenuation (with capacitors to compensate for high frequency signals). The signal ultimately is introduced to a push-pull "Input Amplifier", is processed, and ultimately is passed on to the counter logic circuit. The boundaries if this amplifier are a pair of matched FETs (DUAL FET package) of Q130A/Q130B and -- for our purposes -- Q147 and Q247.

When the "TRIG SOURCE" position is selected, the signal from the 20A/20B connector pins is routed through an energized "Trigger Source Amplifier" comprised of Q216 and Q218 whose output is sent to the Q130A/Q130B FETs of the push-pull amp described above.

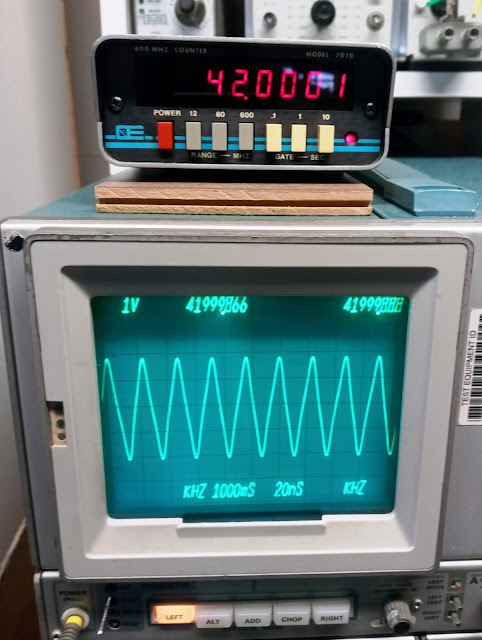

Thus, I chose to measure the signal at the base of Q216 -- the input to the Q216/Q218 amplifier -- as one point and the aforesaid Q147 -or- Q247 bases as the other point.

I ran the test until the counter failed (displayed zeroes) and noted that the bases of Q147 and Q247 lost the signal that appeared there when the test started. The signal at the gate of Q130B was still extant. So I moved the second point "inward" and did a rinse and repeat.

This was done until the second point was the gate of Q130B where I noticed the signal disappear. To make a long story short, I then went through the "Input Amplifier" to determine that it was working.

So here we are. I am convinced the push-pull amplifier is working and I am convinced the "TRIG SOURCE" "Input Amplifier" is working The only question I had was the one I posed in one of my comments above about the overheating relays.

Per a recommendation, I swapped the relays as described but saw no difference. Also, I remain concerned because the other relays were hot tot the touch as well which does not comport with my friend's experience.

Based on the above, I kicked the can a little further down the road here on 7D14 here. Today I embarked on a little experiment. Still puzzling about the relay heating question, I set up the unit to test in the cool of the morning. (We have been having a three-day desert Santa Ana wind condition and the bench area was a little warmish. It was cooler today.)

I propped a fan up to the side of the unit and fired it up. Succinctly, it ran for six hours rock-solid, dead on perfect without any problems. Moreover, the three relays on the front of the board that had heated up in the past were merely warm. Interesting to note, however, the two relays at the back of the board -- K125 and K252 - were hot.

So I am forced to conclude that something is causing those relays -- the SPDT ones, at least -- to head up. I mostly understand the circuit (as I explained to Harvey) but do not know why the relays are heating. I do know there now is a correlation between the plug-in failure and the excessive heat.

..and all this with a Rigol DS1102E sitting on the bench to boot!